- Home

- About us

- Solutions

- Food Processing

- Packaging Solutions

- Cartoning Solutions

- Filling Equipment

- Horizontal Flow-Wrappers

- Labelling Machines

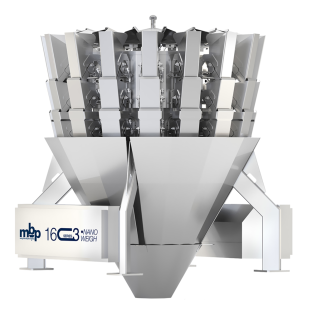

- Multi-Head Weighers

- Overwrapping Machinery

- Palletizing Solution

- Shrink Wrappers

- Vertical Form Fill Seal

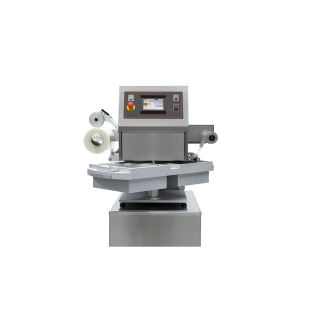

- Thermoformers & Tray Sealers

- Sachet & Stick Pack & End of line packaging Machines

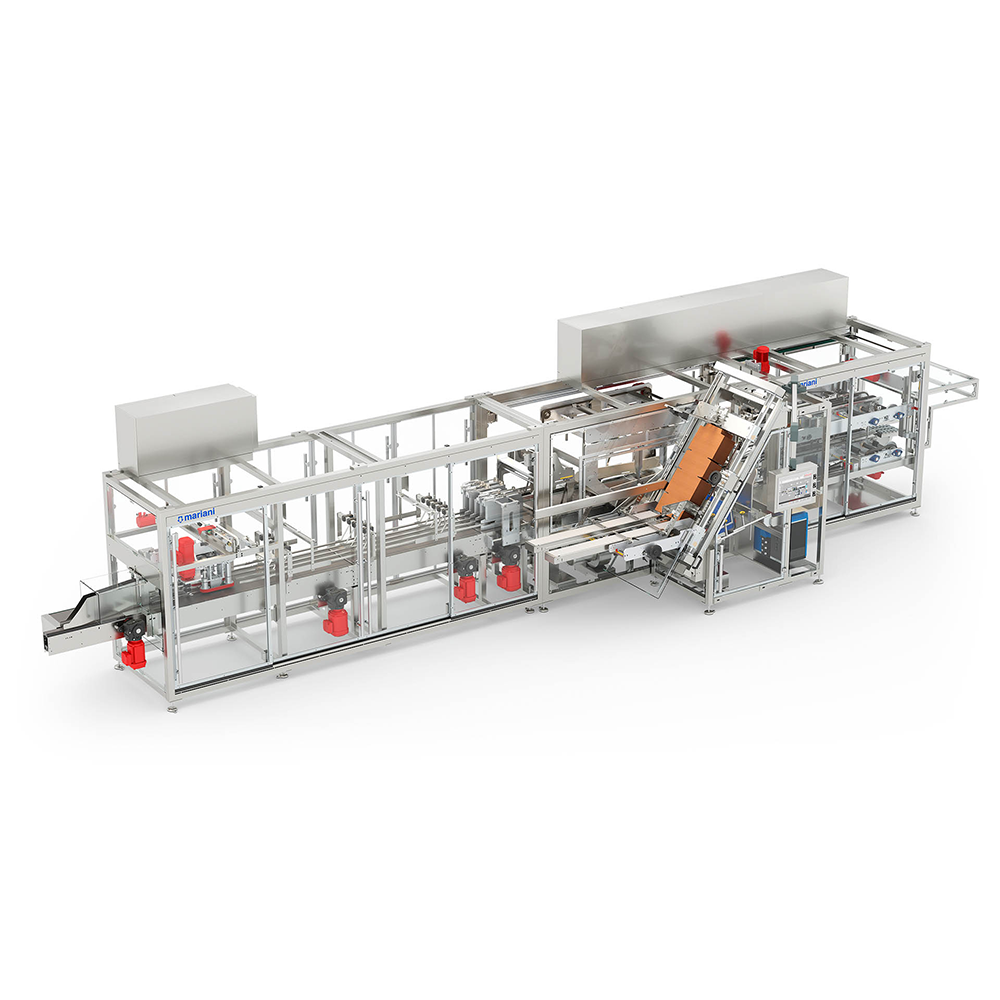

- Fully Automated Compelete Packaging Lines

- Coding & Traceability

- Product Inspection

- Industrial Scales

- Industries

- Services

- Events & Blogs

- Careers

- Contact us