The Ultimate Guide to Vertical Fill and Seal Machines: Precision and Efficiency in Modern Packaging

In the fast-paced world of manufacturing and production; efficiency, reliability, and hygiene are not just goals, they are the bedrock of a successful operation. At the heart of many packaging lines, from food and pharmaceuticals to chemicals and hardware, lies a workhorse that makes it all possible: the Vertical fill and seal machine.

This sophisticated piece of engineering is more than just a machine; it’s a complete packaging solution. But what exactly is a Vertical fill and seal machine, and how can it transform your business? For companies like Anasia Industrial Solutions, which is dedicated to providing top-tier industrial solutions, understanding this technology is key to advising our clients on making the most strategic investment for their growth.

This definitive guide will delve deep into the world of the Vertical fill and seal machine, exploring its core principles, unparalleled advantages, and the critical factors to consider before integrating one into your production line.

What is a Vertical fill and seal machine?

At its core, a Vertical fill and seal machine is an automated system designed to form, fill, and seal packages from a single, continuous roll of flexible film. Unlike horizontal systems that pre-form bags, the process in a Vertical fill and seal machine is, as the name implies, vertical.

The packaging material, a reel of flat film, is drawn upward into the machine. It is then shaped around a specially designed forming tube, creating a continuous tube of film. The back seal is created longitudinally, forming the package’s spine. After the product is placed in the forming tube, the cross-sealing jaws perform two tasks: they seal the top of the filled bag and the bottom of the next package to be formed, while also cutting the individual pouch free.

This elegant, continuous motion is what makes the Vertical fill and seal machine so incredibly efficient for a vast range of products. It’s a testament to how a single Vertical fill and seal machine can streamline an entire packaging segment.

Unpacking the Key Features of a Modern Vertical fill and meal machine

When evaluating a Vertical fill and seal machine, it’s crucial to look beyond the basic function and understand the features that drive performance, consistency, and safety. Leading manufacturers like PFM build their machines with several critical components:

1- Versatility in Film and Packaging Styles

A top-tier Vertical fill and seal machine is not a one-trick pony. It should handle a wide array of flexible packaging materials, from simple polyethylenes to complex multi-layer laminates. Furthermore, modern machines can produce various pouch styles, including:

– Pillow bags: The standard, most common type.

– Gusseted bags: For products requiring a stable, flat-bottomed base.

– Bags with a shaped top: For enhanced presentation.

This adaptability ensures that a single Vertical fill and seal machine can be reconfigured for different product lines or marketing needs.

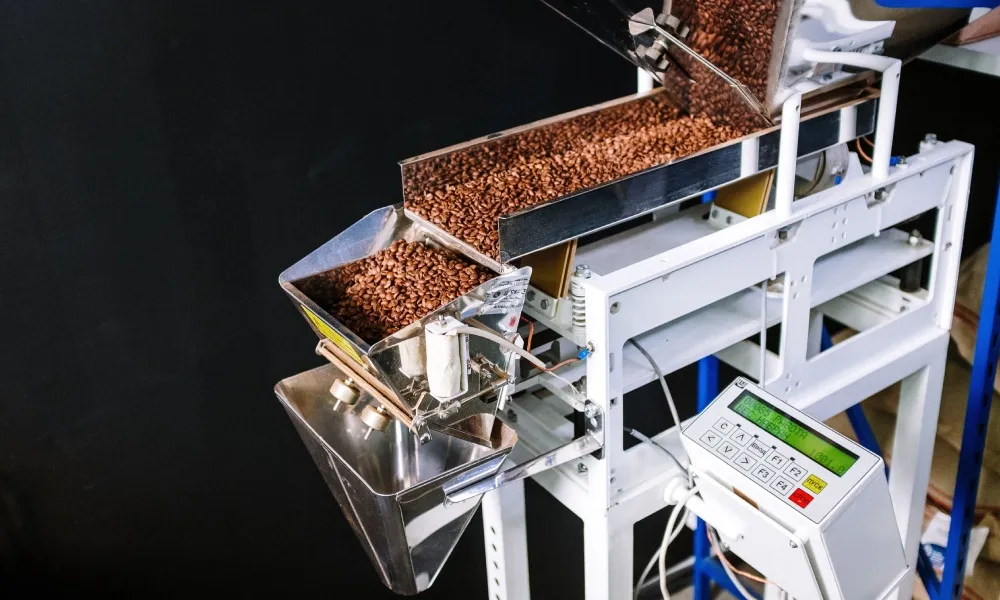

2- Precision Dosing Systems

The “fill” in Vertical fill and seal machine is arguably its most critical operation. Accuracy is paramount to avoid product giveaway and ensure compliance with weights and measures regulations. These machines can be equipped with various filling systems tailored to the product’s nature:

– Volumetric Fillers: Ideal for free-flowing products like granules, powders, or seeds.

– Auger Fillers: Essential for precise dosing of powders, from flour to chemical compounds.

– Liquid Fillers: Engineered for handling viscous liquids, sauces, or oils without drips or spills.

The integration of these precise systems directly onto the Vertical fill and seal machine creates a seamless, error-resistant packaging process.

3- Robust Sealing and Cutting Mechanisms

The integrity of the final package rests on the quality of the seal. A high-performance Vertical fill and seal machine employs heated jaws that apply consistent pressure and temperature to create strong, hermetic seals. The cutting mechanism, often integrated into the same jaws, must provide a clean, sharp cut for a professional-looking finish. The reliability of this component is non-negotiable for maintaining packaging speed and preventing leaks.

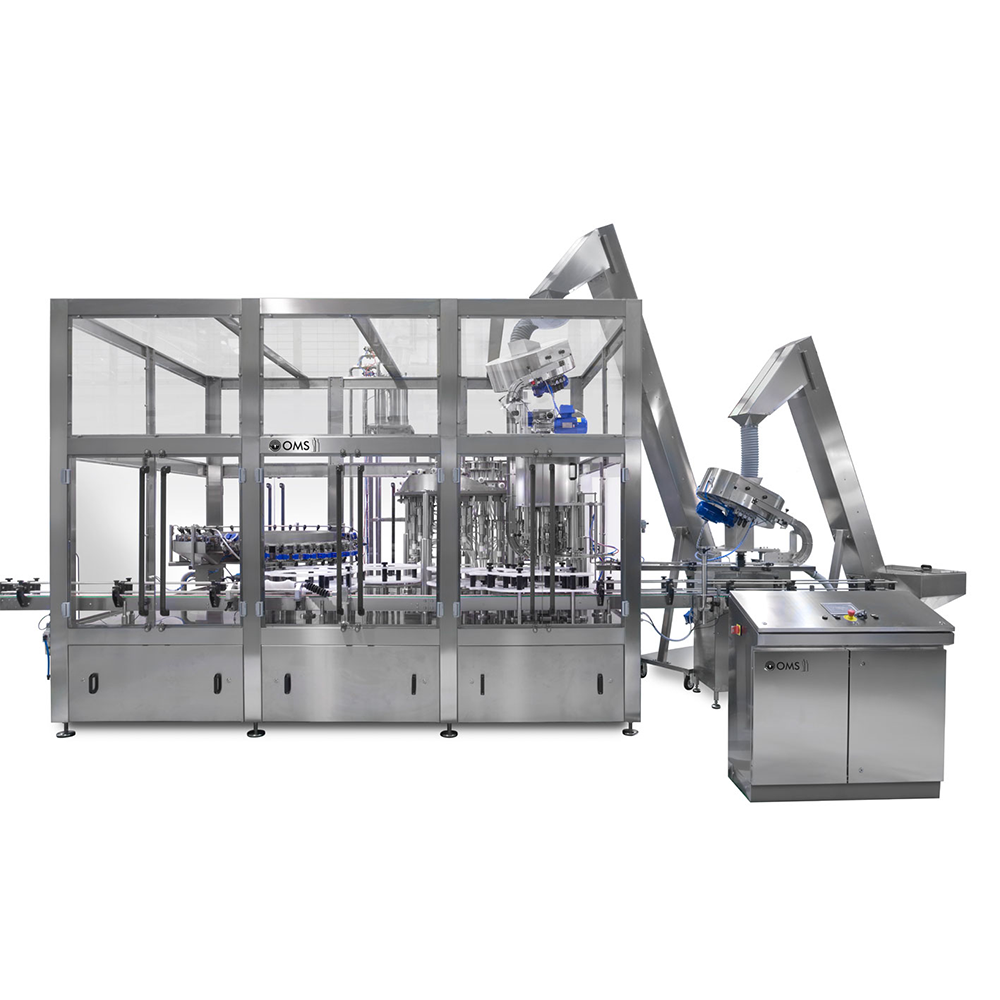

4- Hygienic and Sanitary Design

Especially in food and pharmaceutical applications, hygiene is a critical factor. A well-designed Vertical fill and seal machine will feature easy-to-clean surfaces, minimal crevices where product or debris can accumulate, and often comply with industry-specific sanitary standards. Stainless steel contact parts and easily accessible components are hallmarks of a machine built for demanding environments.

5- User-Friendly Control Systems

Modern automation is defined by its interface. Today’s advanced Vertical fill and seal machine is governed by an intuitive PLC (Programmable Logic Controller) and HMI (Human-Machine Interface). This touchscreen panel allows operators to manage everything from film tracking and seal temperatures to production counts and recipe storage, making changeovers faster and reducing operational complexity.

The Multitude of Applications: Where a Vertical fill and meal machine Excels

The versatility of the Vertical fill and seal machine is one of its greatest strengths. Its application spans numerous industries, proving its value as a universal packaging solution.

1- Food Industry: This is a primary domain for the Vertical fill and seal machine. It is perfectly suited for packaging snacks (chips, nuts, pretzels), pasta, rice, flour, sugar, coffee, frozen vegetables, and candy. The ability to incorporate features like gas flushing (for Modified Atmosphere Packaging) also makes it ideal for preserving freshness in products like cheese and meat.

2- Pharmaceutical and Medical: Precision and hygiene are important here. The Vertical fill and seal machine is used to package sterile medical devices, single-dose powders, herbal teas, and cotton wool.

3- Chemical and Detergent Industry: From laundry pods and powdered detergents to industrial chemicals and fertilizers, the Vertical fill and seal machine provides a safe, contained, and efficient packaging method, often with specialized augers for aggressive or hazardous materials.

4- Hardware and Components: Screws, nails, bolts, and other small hardware items are perfectly portioned and protected by a Vertical fill and seal machine, allowing for clear visibility and retail-ready presentation.

This wide-ranging applicability demonstrates why the Vertical fill and seal machine is considered a cornerstone of modern industrial packaging. Partnering with an expert like Anasia ensures you select the right model for your specific sector.

A Closer Look at the Technical Specifications

To make an informed decision, it’s helpful to understand the typical capabilities of an industrial-grade Vertical fill and seal machine. While specifications vary by model and manufacturer, here is a general overview of what to expect:

Understanding these specs is crucial, but it’s the integration and support that truly unlock the potential of your Vertical fill and seal machine. This is where Anasia Industrial Solutions role becomes invaluable, providing the technical expertise to match the machine’s capabilities with your production goals.

Choosing the Right Vertical Fill and Seal Machine: A Strategic Guide for Your Business

Selecting a Vertical fill and seal machine is a significant investment. Rushing this decision can lead to bottlenecks, compatibility issues, and lost revenue. Here is a strategic framework to guide your selection process:

1- Define Your Product Characteristics.

Is your product a powder, a granule, a liquid, or a solid? Each requires a specific dosing system. Its flowability, abrasiveness, and density will directly influence the type of filler you need on your Vertical fill and seal machine.

2- Determine Your Required Output.

What are your current and projected production volume? The speed of a Vertical fill and seal machine is measured in cycles per minute, but real-world output depends on bag size and product. Ensure the machine you choose can meet your peak demands without constant strain.

3- Specify Your Packaging Materials.

What type of film will you use? Is it a simple monolayer or a complex laminate? Does your product require a high-barrier film or Modified Atmosphere Packaging (MAP)? The Vertical fill and seal machine must be compatible with your chosen material and capable of creating a strong, reliable seal.

4- Consider Your Operational Environment.

Will the Vertical fill and seal machine operate in a dry environment, or will it require frequent wash-downs? For food and pharmaceutical use, a machine with a high IP rating and sanitary design is non-negotiable.

5- Plan for the Future.

A Vertical fill and seal machine is a long-term asset. Consider its flexibility. Can it handle different bag styles? How quick and easy is a product changeover? Buying a versatile machine from the start can save money and reduce downtime as your product line grows.

Why Your Investment in a Vertical fill and seal machine is a Step Towards Sustainable Growth

The decision to integrate a Vertical fill and seal machine into your operations is a move toward greater profitability and market competitiveness. Here are the key benefits:

1- Dramatically Increased Efficiency: Automation drastically reduces manual labor, increases output, and ensures consistent operation 24/7 if needed.

2- Superior Product Protection: The hermetic seals and use of appropriate barrier materials extend shelf life, maintain product quality, and reduce spoilage and waste.

3- Significant Material Savings: Precision dosing minimizes product giveaway, and using film from a reel is often more cost-effective than pre-made bags.

4- Enhanced Brand Image: A professionally packaged product, with consistent and clean seals, builds consumer trust and stands out on the shelf.

5- Operational Flexibility: The ability to quickly switch between products and package sizes allows you to respond agilely to market demands.

Anasia Industrial Solutions: Your Partner in Packaging Automation

Navigating the complex landscape of packaging machinery requires a partner you can trust. Anasia Industrial Solutions is committed to being more than just a supplier; we are your strategic ally in automation. We understand that a Vertical fill and seal machine is a critical component of your production line. Our team of experts is dedicated to providing comprehensive support, from the initial consultation and machine selection to installation, training, and ongoing maintenance.

We help you cut through the complexity and find the perfect Vertical fill and seal machine that aligns with your unique operational needs and ambitions for growth.

Ready to transform your packaging line with the efficiency and reliability of a Vertical fill and seal machine? Contact Anasia Industrial Solutions today for a personalized consultation. Let’s build the future of your production, together.

Comments are closed